Post-Tensioned Concrete

POST-TENSIONED CONCRETE IS BUILT TO TAKE ON THE HARSHEST OF CONDITIONS

Did you know that over 50% of the construction budget for your outdoor track is invested in the high-performance track surface? Asphalt irregularities, including cracks, settling and uncorrected deviations in the planarity of the asphalt base or wear course, can telegraph or reflect through to the running track surface. Use PTC and avoid this risk.

WHY YOU SHOULD CONSIDER PTC OVER ASPHALT?

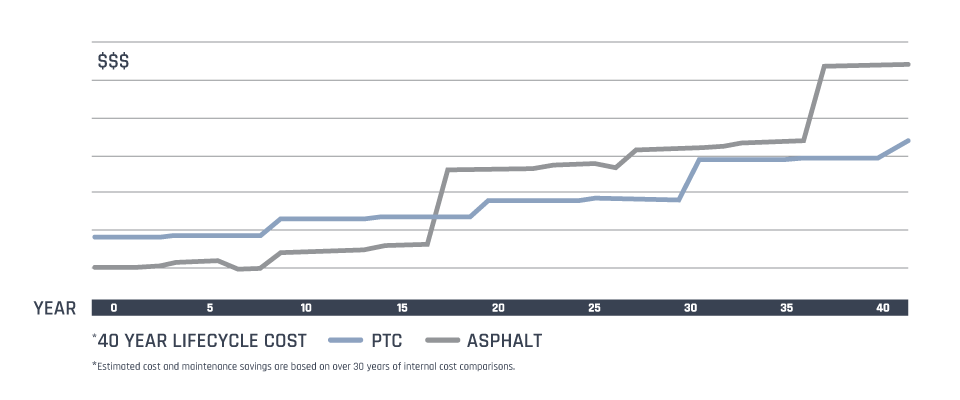

With an expected lifecycle of nearly 50 years, a (PTC) post-tensioned concrete track subbase can last nearly three times longer than an asphalt base. Requiring only minor repairs every decade, post-tensioned concrete subbase saves not only money but also time.

DURABILITY IN POOR SOIL AREAS

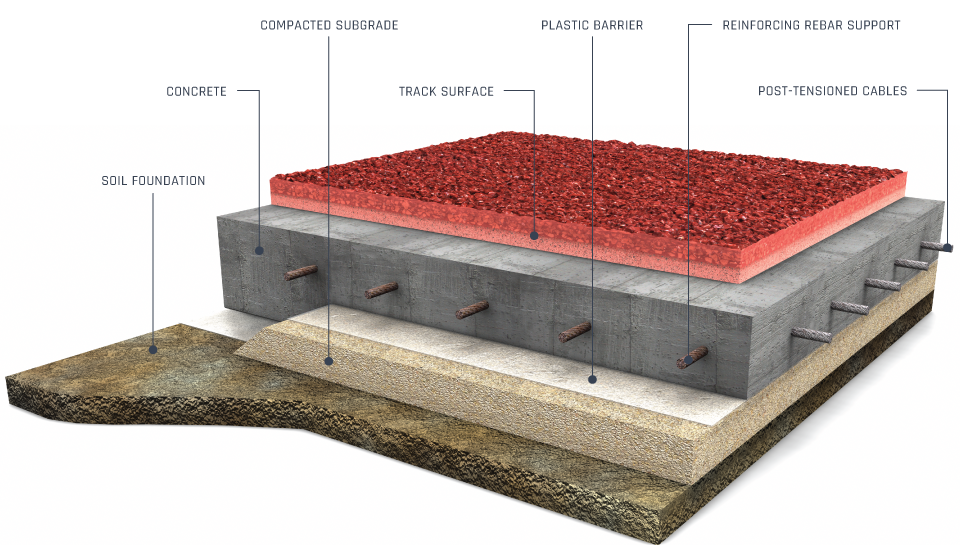

PTC has long been the solution to dealing with poor soil conditions. If movement occurs in expansive soil, instead of moving, the concrete slab actually floats and performs independently due to the constant compression.

RESISTANCE TO CRACKING AND BASE SURFACE REPAIR

Engineered to offer maximum durability, PTC is the answer to crack control. Resistant to weather fluctuations and extreme conditions. The base has proven its long-term structural strength.

IMPROVED DRAINAGE

PTC offers superior drainage control, eliminating any pools of waters that may settle in low areas. In colder climates, water can seep into cracks and freeze, causing instability and premature deterioration.

EXISTING SITE REMEDIATION

Replacing a failing asphalt base is easy with post-tensioned concrete. PTC can be installed directly over the existing surface and offer the same long-term lifecycle.

WE BUILT IT TO LAST...SO YOU CAN REAP THE REWARDS

With an expected lifecycle of nearly 50 years, a post-tensioned concrete track subbase can last nearly three times longer than an asphalt base.

Advancements in technology have lowered the initial installation costs, making post-tensioned concrete a viable option.